Tissue Chemistry

Chemtech Empowered By

Innovative Services

We understand the importance of creping chemistry in the tissue mill industry.

We have a range of creping adhesives, release agents, coating modifiers and plasticisers, such as:

- AmiCoat TC series,

- AmiCoat TM series and

- AmiCoat TR series,

This technology allows optimization of your Yankee coating chemistry for the grade of paper you are making. We also offer technical audits with the use of Infra-red technology to improve creping, felt cleaning and wire cleaning operations. Our range of de-inking chemicals ensures that your recycled fibers are of the highest quality. Our de-inking chemicals are used to detach ink from fiber and disperse ink particles during foam flotation, allowing you to produce various grades of paper and board including Tissue, Printing & Writing papers, “white top” board and Newsprint. Enzymes play an important role in tissue wet end fiber treatment, and we offer a range of enzymes to meet specific objectives. We carefully select the appropriate type of enzyme for specific objectives and areas of the tissue making process. Our felt cleaners and conditioners enable continuous running of pulp dryers and paper machines, significantly enhancing productivity. The selection of cleaners and conditioners depends on the type of contaminant in the felt, and the use of a proper

conditioner slows down the rate of contamination.

Value Adding Services

At Chemtech, we have a team of professionals who would work with you to select the most appropriate products and spraying systems, putting into consideration your finished product requirements and if wet end stock chemicals are providing the release and adhesive properties. We could also help you to design the appropriate spray equipment to meet your machine requirements, including spray pattern and nozzle selection to meet operational criterion.

Technical Services

Cost effective Process Pre-engineering program:

1. Process assessment

2. One on One operations interviews

3. Data collection.

4. Service program development

5. Operations training and information sharing

Selection of chemistry based on the systems and process requirement and IESConcept

Design and supply of conventional or automated dosing systems.

ROI and eROI calculation reports

Schedule business review meeting

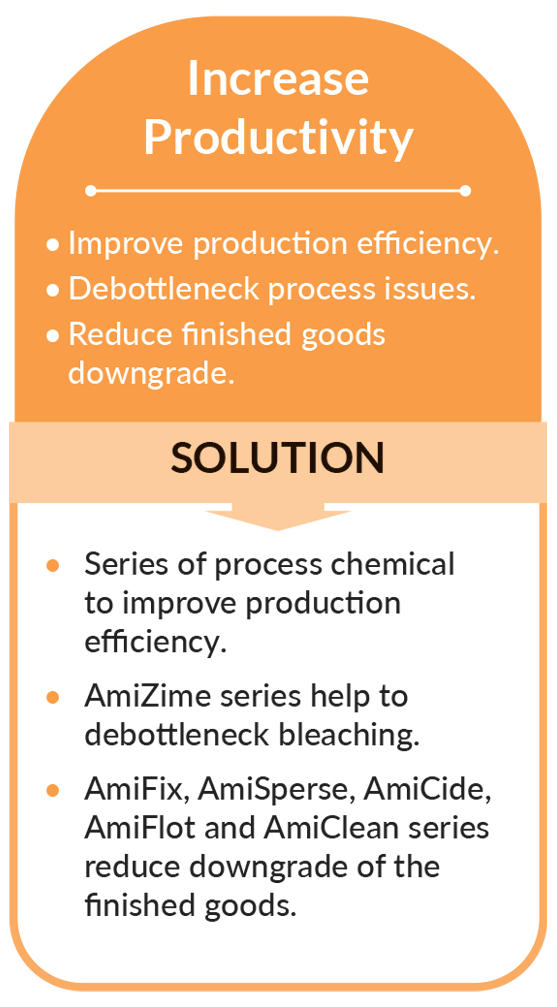

Application services including dosing and stock control, process KPI’s management and more.

Operational Services

Dissolved Pulping and Bleaching Program

- Laboratory Pulp Quality and efficiency Evaluation

- Pitch and colloidal pitch control system,

- Visual inspection of pitch.

- Turbidity of white water at pulp driers

Foam control Program

- Laboratory screening.

- Off-line and On-line entrained air content

measurement systems. - Foam level control strategy.

Microbiological control Program

- Microbiology enumeration;

(Plate count and dip slides) - ATP and ORP

- On-site and Off-site microscopy analysis

- Detailed laboratory deposit analysis

Scaling control in pulp and paper Mill

- Fouling screening

(LOI, XRF, IR, CHNS, CFD analysis) - Stability index

- Scale index

- Corrosion and fouling meters

Machine charge control

- On-line charge analyzer measurement

- Zeta potential testing and control

- Colloidal fixation.

- TSS testing and Turbidity

Wet and Dry strength control

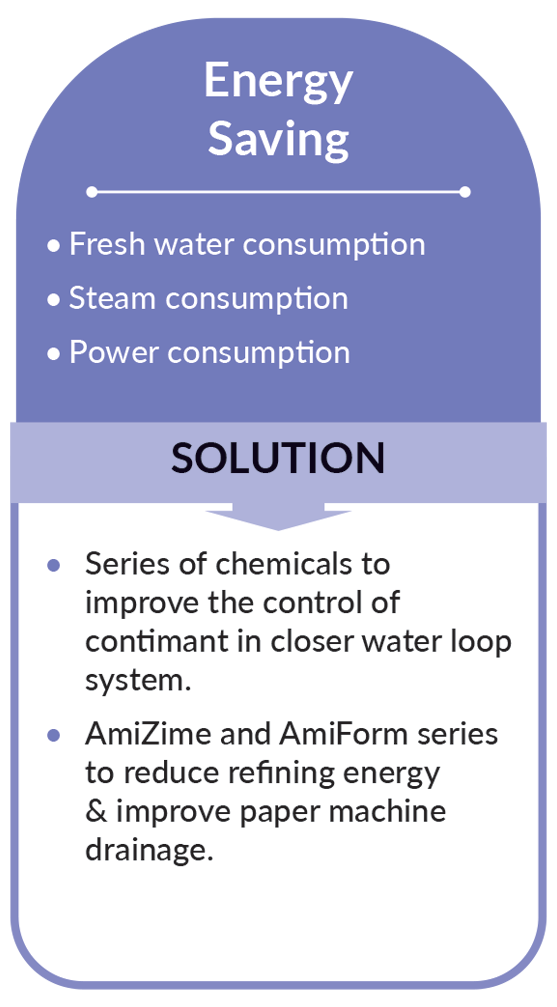

- Energy optimization

- Fines control

- Refiner plate optimization

- New environmentally friendly product introduction.